Products > OCTG

Oil Country Tubular Goods (OCTG)

-----------------------------

API Standard Pup Joint from 2-3/8" to 4-1/2"

API Oil Tubing Pup Joint

1. Size: 2 3/8", 2 7/8", 3 1/2", 4 1/2";

2. End Type: NU & EU;

3. Steel Grade: J55, K55, N80-1, N80-Q, L80-1, P110 ;

4. Specification: API Spec5CT & API 5B;

5. Technique: Cold Drawn or Hot Rolled

6. Feature: with oil on surface to avoid corrosion, high corrosion resistance and long running life.

7. Dimensions and their tolerances of tubing round-thread as per API spec 5B

8. Our tubing pup joint conform to API 5 CT standards, Length: 2FT/3FT/4FT/5FT/6FT/8FT/10FT/12FT and we can make different lengths and sizes according to the customer's requests.

9. Based on the principle of equality and mutual benefit, we provide the products with high quality at competitive price

10. Thread protector Packing: In Bundle or Wooden Cases or by the requirements of customers

10. Supply Ability: 10,000 EA per month

11. Payment Term: L/C, T/T

----------------------------------

Special Steel Grade Tubing and Casing

1.Products for anti-H2S corrosion

Steel Grades: BG80S,BG80SS,HS80S,HS80SS,BG95S,BG95SS,HS95S,HS95SS,BG110S,BG110SS,HS110S,HS110SS

2. Products for anti- CO2 corrosion

Steel Grades: L80-9Cr,L80-13Cr,BG55-1Cr,BG80-1Cr,BG90-1Cr,BG110-1Cr ,BG80-3Cr,BG90-3Cr,BG110-3Cr

Economic products for anti- H2S+CO2+Cl corrosion

Steel Grades: BG80S-3Cr ,BG90S-3Cr

3. High Collapse Casing pipe produced by our mills have good performance for the extremely deep and complex wells.

High Collapse Casing pipe

High Collapse (HC) grades exhibit higher collapse pressure than what is determined by API 5CT/ISO 11960 products.

We provides the High Collapse Series of proprietary steel grades for oil and gas wells where high external pressures are anticipated and collapse resistances higher than API are needed.

In addition to uniform external pressures, the reservoir can exert high pressures due to ground movements or saline strata, subjecting pipes to extreme localized external pressure.

Our mills have developed the high collapse casings such as: 80T, 90T, 95T, 110T, 125T, 80TT, 90TT, 95TT, 110TT, 125TT casings.

·Process control

1) To control strictly the inclusions in steel via the purity steel melting technology.

2) To control strictly the wall thickness and ovality of the tubes during the hot rolling.

3) To guarantee the yield strength and surface quality through the temperature and atmosphere control in the furnace during the heat treatment.

4) Through the second sizing and on line hot straightening after heat treatment, strictly control the residual stress, OD, ovality and staightness.

4. Oil casing pipe for thermal recovery well

| Variety | Size |

Grade |

Connection | Standards | Typical Applications | |

|

OD in |

WT in |

|||||

|

Thermal recovery well used casing |

60.3-339.7 (2-3/8’’-13-3/8’’) |

4.83~15.88 (4.6-86) |

HS80H | S/L/B/HSM-1/HSM-2/HSN |

HK29-2011 Or technical specification |

Heavy oil and heat-resistance |

| HS90H | ||||||

| HS95H | ||||||

| HS110H | ||||||

| HS125H | ||||||

New Product

1. Anti-Collapsing casing series

Self-development:

High collapsing Series:CB80T、CB90T、CB110T、CB125T、CB130T、CB140T、CB150T、CB155T、CB160T

Super High collapsing Series:CB80TT、CB90TT、CB110TT、CB125TT、CB130TT、CB140TT、CB150TT、CB155TT、CB160TT

High collapsing + High Anti-Corrosion:CB80TS/CB80TSS、CB90TS/CB90TSS、CB95TS/CB95TSS、CB110TS/CB110TSS

Features:

According to the development of oil and gas wells, Chang Bao’s collapsing series casing has the following characteristics:

Diameter is round and oval is little----- oval≤ 0.5%

Thickness is high accurate and distance is little ---- the same cross-section inequality is ≤ 9.5%

Strength is high and performance is steady - Heat treatment is by quenching and tempering

Low residual stress

Applications:

Deep and super deep well

To separate rock salt layer and soft layer

Well with the H2S Corrosion condition

2. High and super high strength casing series

Self-development:

Q125, CB130, CB140, CB150, CB155 Series

Features:

High impact toughness;

Testing inside / outside surface of vertical / horizontal L2 level, 100% of WT test; Fitting and pipe body have high strength, and to ensure the internal pressure, external collapse resistance and the overall connection performance well.

Applications:

Mainly used for deep and super deep oil and gas exploitation.

3. Anti-corrosion oil casing series

Self-development:

Anti-H2S Corrosion OCTG Series: CB80S, CB90S, CB95S, CB110S

High Anti-H2S Corrosion OCTG Series: CB80SS, CB90SS, CB95SS, CB110SS

Low Cr anti-CO2 Corrosion OCTG Series: CB90-3Cr, CB95-3Cr, CB110-3Cr, CB125-3Cr

Low Cr anti-CO2+H2S Corrosion OCTG Series: CB80S-3Cr, CB90S-3Cr, CB95S-3Cr, CB110S-2Cr

Low Cr anti-CO2+High Anti-H2S Corrosion OCTG Series: CB80SS-3Cr, CB90SS-3Cr, CB95SS-3Cr

High Cr anti-CO2 Corrosion OCTG Series: CB80-13Cr, CB110-13Cr

High Cr anti-CO2+H2S Corrosion OCTG Series: CB80S-13Cr, CB110S-13Cr

Features:

Steel purity - P ≤ 0.010%, S ≤ 0.006%;

Performance is steady - all cross-sectional area of steel after quenching can receive more than 98% martensite, there will be fine even tempered sorbite organization after tempering

Stress corrosion - to eliminate residual stress, surface corrosion of the structure to form one or several atomic layer of the high stability of alloy corrosion resistance group content of oxide film

Homogeneous - grain size ≥ 8 level, uniform hardness;

Applications:

Wells with CO2 corrosion condition.

Wells with CO2+H2S corrosion condition

Wells with CO2+H2S+Cl- corrosion condition

4. Heavy oil thermal recovery pipes

Self-development:

CB80H, CB100H, CB110H Series

Features:

Performance of tensile under short-time high temperature condition is high. The decline of the performance is little with the temperature rising.

Applications:

Used for prolonged heat exploitation under 350℃ working temperature,

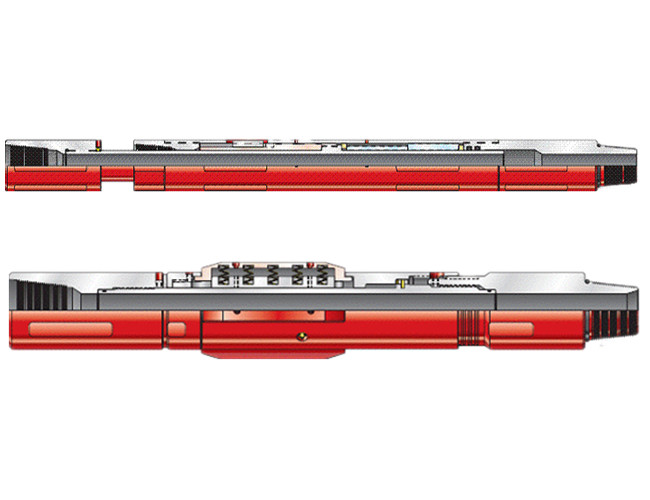

5. Perforating gun barrel

Self-development:25Mn2V, 30CrMo, 32CrMo4 Series

Features:

High precision control of product size, performance and stability

Applications:

Used for the manufacture of oil and gas well perforating gun body.

R & D situation:

Perforation barrel projects are used 25Mn2V, 32CrMo4 (30CrMo) material for trial, the results after testing, performance, size, testing are in line with set requirements

6. Water Injection Pipe

Self-development:

Low Cr anti CO2, Cl-, H2S corrosion of water injection oil casing series

Features:

| Style | Anti-CO2 corrosion performance | Anti-H2S corrosion performance | Connection strength with the body | Anti-corrosion performance of connection |

General Performance |

Cost |

| Protective Coating | Part corrosion | Failed | Bad | Bad | Good | High |

| Plating | Part corrosion | Failed | Bad | Bad | Good | High |

| Stainless steel lining | Part corrosion | Failed | Bad | Bad | Good | High |

| Nitriding | Depends on the thickness of nitrided layer | Failed | Good | Depends on the thickness of nitrided layer |

Plastic Lower |

High |

| KWOMlow Cr product | Adjustment according to condition | Good | General good | Adjustment according to condition | Good | Depends on the alloy content |

Applications:

R & D situation:

KWOMwater injection pipes have been successfully tested. The evaluation of test performance can meet the requirements of the conditions for sale

7. Anti- H2S corrosion line pipes

Product standards, steel grade:

Standard:API SPEC 5L、ISO3183、GB/T9711

Steel Grade:L245NCS、L290NCS、L360NCS、L290QCS、L360QCS、L415QCS、L450QCS

Features:

According to the development needs of oil and gas wells, Chang Po H2S corrosion resistant line pipe has the following characteristics:

Pure steel, in which: P ≤ 0.015%, S ≤ 0.003%; performance and stability, the composition of the uniform

Applications:

Transportation of oil and gas with H2S corrosion condition.

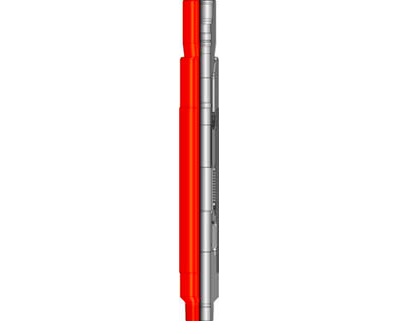

8. Premium connection series

Self-development:

HQST1;HQSC1;HQXT1;HQXC1;HQXST1;HQXST2;HQXSC1;

Cooperative development:

Integ-max、Flush-max、Super-max

Premium connection characteristics:

Considering the requirement of internal and international oil field, KWOMHQST1/HQSC1 premium connection has the following characteristics:

High strength thread - buttress thread

Good in sealing performance - double metal seal structure

Without vortex and erosion - the hole smooth transition

Coupling threads and sealing surface by the copper alloy treatment - anti-galling performance

Applications:

Deep and super deep wells

High-pressure gas wells

Directional wells, wells and other structures requires complex formation connection strength and high sealing performance of oil and gas wells

Corrosion-resistant shaft

R & D situation

Self-development:

KWOMHQST1 Connection :2-3 / 8 ",2-7 / 8" ,3-1 / 2 "tubing products have been successfully developing and debugging, with production capacity.

KWOMHQSC1 Connection: 5 ",5-1 / 2" casing products have been successfully developing and debugging, with production capacity.

KWOMHQXSC1 Connection: 5 "casing is in debit-based authentication .

Co-development of Premium connection.

INTEG MAX Connection: 3-1/2 EU has been successful development and debugging, with production capacity.

SUPER-MAX Connection: 2-7/8 NU has been successful development and debugging, with production capacity.

FLUSH-MAX Connection: 2-7/8 NU has been successful development and debuggin

---------------

Manufacturing HOT ROLLED、COLD DRAWN、SEAMLESS 、ERW、LSAW、

SSAW、SMLS Method Out

Diameter Wall

Thickness Premium Threads APIC Threads Steel Grade Length Range Test

1.66 INCH ---- 4 1/2 INCH 0.1 INCH ---- 1 INCH

Vam series , Hunting series, Tenaris- Hydril series , JFE series Round thread(8tpi, STC and LTC), Buttress thread (5tpi, BTC)

J55/K55, N80-1, R95, M65, N80-Q, L80-1, L80-9Cr, L80-13Cr, C90-1, T95-1, C110, P110, Q125, V150 API STANDER R1、 R2 、R3

NDT Pressure Test Third Party Certification Non-destructive Thread Inspection Hydrostatic test Drifting Test Chemical Analysis

-----------------------

Products

+Drilling Equipment

- Casing Scraper

- balck rhino Non rotating Casing Scrappe

- RazRdillo Casing Scraper

- multiple activation autolock bypass tools

- Non-rotating wellbore casing scraper

- Wellbore Cleaning up tools

- Drill Pipe

- Downhole Motor

- KINGWELL Stabilizer-sleeve type

- Deflecting tools and mill tools

- drill bits

- Cross Coupling Cable Protector

- KINGWELL Underreamer

- Reammate Underreamer

- mill shose

- KINGWELL Raiseboring drill pipes

- Stabilizer

- future drill tools

- RGS Remote Gauge Stabilizer

- Shock Tools

- Casing and Pipe cutting equipment

- HORNET Series Drilling Tools

- Hydraulic Oscillator

- Hydraulic Thruster

- Drill Bit

- Jar Intensifier Type YJQ

- Overshot

- Full opening safety valve

- Top Drive Drilling Tools

- Hole Opener

- Drill Hydroscillator

- Lubricated Fishing Bumper Sub Type BXJ

- Drilling Jar

- Continuous Circulating Valve

- Inside Blowout Control Tools

- Multi-cycle Circulating tools

- Hydraulic Jar Type YSJ

- Drilling Accelerator Type ZJQ

- Fishing Bumper Sub Type KXJ

- Model DJQ Cable Jar

- Model ZTX Highly-Efficient Vibration Resi

- Super Fishing Jar Type CSJ

- Surface Bumper Jar Type DJ

- Surface Bumper Jar Type DX

- Two-action Drill Accelerator Type SZJQ

- Fishing Spear

- Junk Basket

- Wear Preventive Subs

- Kelly

- Heavy Weight Drill Pipe

- Drill Collar

- Magnetic Fishing Tool

- Die Collar

- Casing Scraper

- Shock Absorber

- Pup Joint

- Subs

+Rig Accessories

- KWDWS Water Cooling Eddy Current Brakes

- BOP

- Christmas Tree

- An Overview of OCTG Piping Inspection Met

- Casing and tubing

- Wire-wrapped Screen

- ASTM A53 GRADE B SEAMLESS

- flange

- EN 10217 Welded steel pipe

- Oil Country Tubular Goods (OCTG)

- ASTM A333 Grade1 Carbon Steel Pipe

- Coiled Tubing

- High Pressure Fluid Control Products

- Coupling

- API 5CT Hot Rolled Tubing Pup Joint

- Ram Type and Annular Type Blowout Prevent

- Solids Control System

- Crown Block

- F-1600HL Mud Pump

- Coiled Tubing BOP

- drilling line

- Kill Manifold and Choke Manifold

- F-2200HL Mud Pump

- Ironroughneck

- Hydraulic Disc Brake System

- Mud Hopper and Mud mixing pump

- Gate Valve

- Top Drive

- OCTG

- Butterfly Valve

- Globe Valve

- Ball Valve

- Plug Valve

- Choke Valve

- Check Valve

- Casing Hanger and Tubing Hanger

- Tubing Spool and Casing Spool

- Slip

- Tong

- Elevator

- Tubing Head

- Casing Head

- Drawworks

- High and Low Pressure Pipe Manifold

- Forgings for Flange/Valve/Shaft/Gear

- Forging for Downhole Tools

- Pipe Mould

- Die Steel/Tool Steel

- Mandrel Bar

- Rolling Mill Roll

- Corrugated roll

- Travelling Block and Hook

- Rig Swivel

- Drilling Rig Mast

- Rotary Table

- Mud Pump

- Vacuum Degasser

- Other Solid Control Equipment

- Shaker Screen

- Submersible Slurry Pump

- Shear Pump

- Mud Agitator

- Centrifugal Pump

- Decanter Centrifuge

- Desilter

- Desander

- Mud Cleaner

- Linear Motion Shale Shaker

+APR Drill Stem Testing Tools

- Rupture Disk (RD) Sampler

- Slip Joint

- Hydraulic Jar

- Shock Absorber

- Gauge Carrier

- Drain Valve

- OMNI Valve

- LPR-N Valve

- Safety Valve

- Safety Joint

- Circulating Valve

- RTTS Packer

- Super Safety Valve/Subsea Safety Valves (

- Hydro Trip Pressure Sub

- Surface Well Testing system

- APR Pressure-controlled Formation Tester

- Full-bore Compensating Pipe

- Retrievable Service Packers

- Fullbore DST string

- DST TOOLS specification

- Subsurface Control Valve (SSC) Storm Vavl

- Champ v Packer

- Storm Valve

- Tester Valve